Carbide Tooling | Williams Industrial Supply Inc.

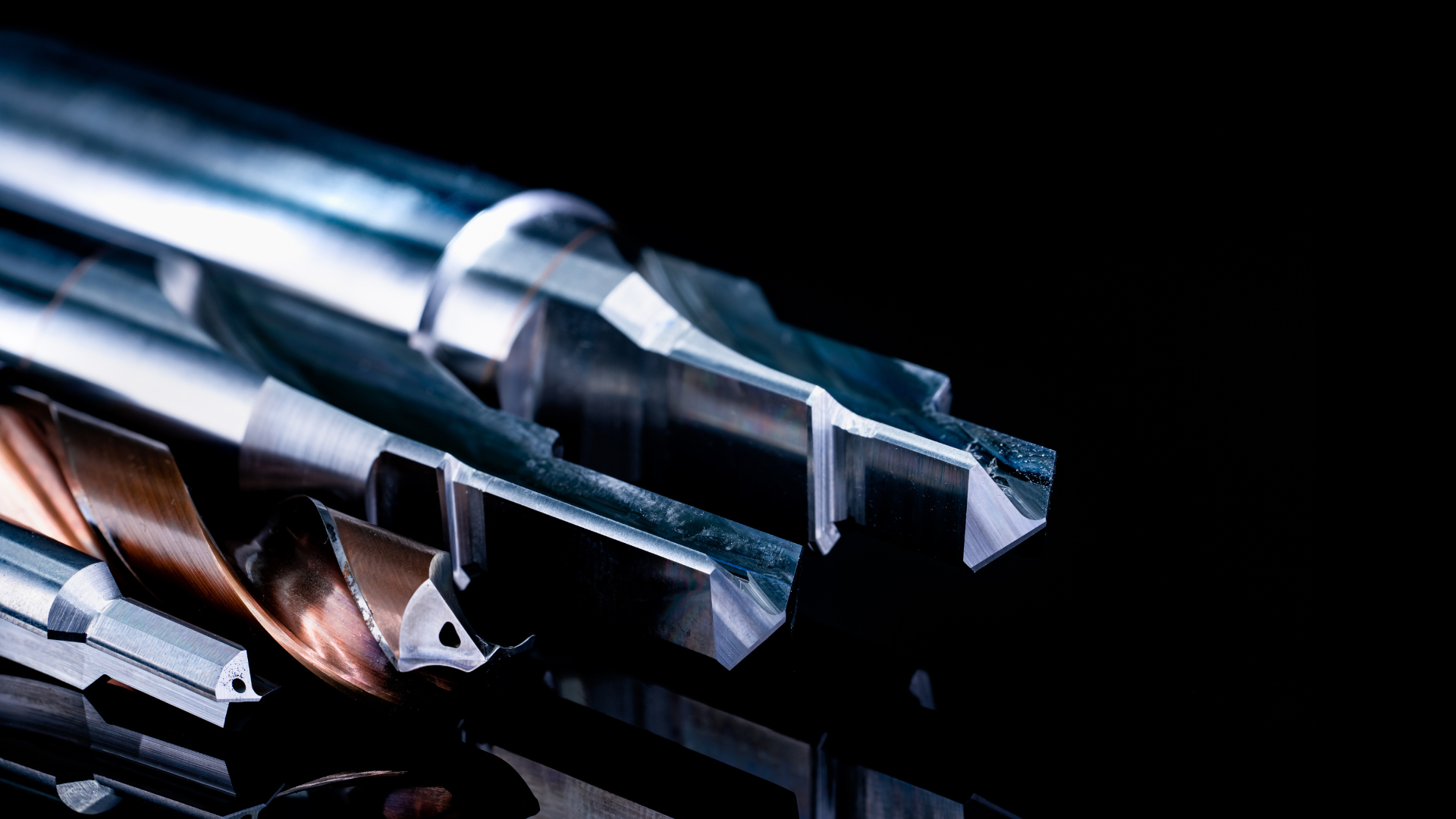

Precision Carbide Tooling for CNC and Manual Machining

At Williams Industrial Supply Inc., we specialize in high-performance carbide tooling solutions for machine shops, fabricators, and manufacturers throughout Scranton and Northeastern PA. Whether you’re cutting hard metals on a CNC mill or facing parts on a lathe, the quality of your carbide tooling determines speed, finish, and tool life.

We stock and source a wide range of carbide inserts, end mills, boring bars, tool holders, and specialty tools — all from industry-leading brands, and all supported by our in-house product expertise.

As a stocking distributor, we offer faster access, better service, and real application support — not just part numbers.

Our Carbide Tooling Product Line

We carry carbide tools for milling, turning, grooving, threading, and drilling operations — covering most machine types and cutting applications.

Carbide Inserts

- Turning Inserts (CNMG, DNMG, SNMG, etc.)

- Milling Inserts

- Parting and Grooving Inserts

- Threading Inserts

- Boring Inserts

Available in multiple geometries, chipbreakers, and grades for steel, stainless, aluminum, and superalloys.

Solid Carbide Tools

- End Mills (2-flute, 4-flute, variable helix, roughing)

- Drill Bits (stub, jobber, and extra length)

- Reamers

- Burrs & Rotary Files

Tool Holders & Components

- Indexable Tool Holders

- Boring Bars

- Collet Chucks

- VDI Tooling

- Threading Tool Systems

- Milling Cutter Bodies

- Modular Tooling Systems

Special Purpose Tools

- Coolant-Through Carbide Tools

- Radius and Chamfer Tools

- Custom Ground Tools (on request)

We support both standard and high-speed machining environments, with tooling available for ferrous and non-ferrous materials, composites, castings, and hardened steels.

FAQs – Carbide Tooling

Can you match carbide inserts from another supplier?

Yes. We specialize in cross-referencing major catalogs like Grainger, MSC, and Kennametal. Bring us your part number — we’ll find your match.

Do you carry both indexable and solid carbide tools?

We do. From indexable turning tools to solid carbide drills and end mills, we carry options for roughing, finishing, and specialty operations.

Do you offer coolant-through tooling?

Yes. We carry and source a variety of coolant-fed tooling solutions, especially for high-speed CNC environments.

Can you support custom or specialty tool requests?

Absolutely. We can help source or manufacture special tools — or advise you on equivalent off-the-shelf options.

Serving Shops Across Northeastern Pennsylvania

We’re proud to support:

- CNC Machine Shops

- Aerospace & Defense Contractors

- Mold & Die Makers

- Fabrication Shops

- Job Shops

- Municipal & Technical Education Programs

- Automotive & Powertrain Suppliers

Our carbide tools are used in turning centers, vertical mills, horizontal machining centers, Swiss lathes, and multi-axis machines.

Trusted Brands in Stock or Available to Order

We distribute carbide tooling from a wide range of respected manufacturers, including:

See More

- Kennametal

- Seco

- Sandvik Coromant

- Iscar

- Mitsubishi Materials

- Tungaloy

- Walter Tools

- Guhring

- Kyocera

- Allied Machine

- Sumitomo

- Niagara Cutter

- SGS

- OSG

- Hertel

- Widia

- Tool-Flo

- Ingersoll

- Cleveland

- Accupro

- YG-1

We also support cross-referencing from MSC, Grainger, Travers Tool, and other catalogs — just give us the part number, and we’ll get you a direct match or better-value equivalent.

Carbide Grades & Coatings Available

Tool life and performance depend on using the right carbide substrate and coating for your job. We stock tools and inserts with:

- C2, C5, and C6 Grades

- TiN, TiCN, TiAlN, AlTiN, and PVD Coatings

- Uncoated options for non-ferrous or fine-finishing needs

Not sure what grade or geometry is best? Bring us your application specs — we’ll help you match the right insert or cutter to your speed, feed, and material.

Precision Tools. Fast Delivery. Local Expertise.

For shops that can’t afford downtime, Williams Industrial Supply offers the carbide tooling and expert support you need to stay competitive. Let us help you improve tool life, reduce cycle times, and simplify your supply chain — all from our Scranton-based warehouse.

Call

(570) 347-2015, email

williamssupply@epix.net, or visit us at 916 N Washington Ave, Scranton, PA — we’re here Monday through Friday, 8:30 AM to 5:30 PM.