Top 5 Industrial Cutting Tools Every Fabrication Shop Needs

Top 5 Industrial Cutting Tools Every Fabrication Shop Needs

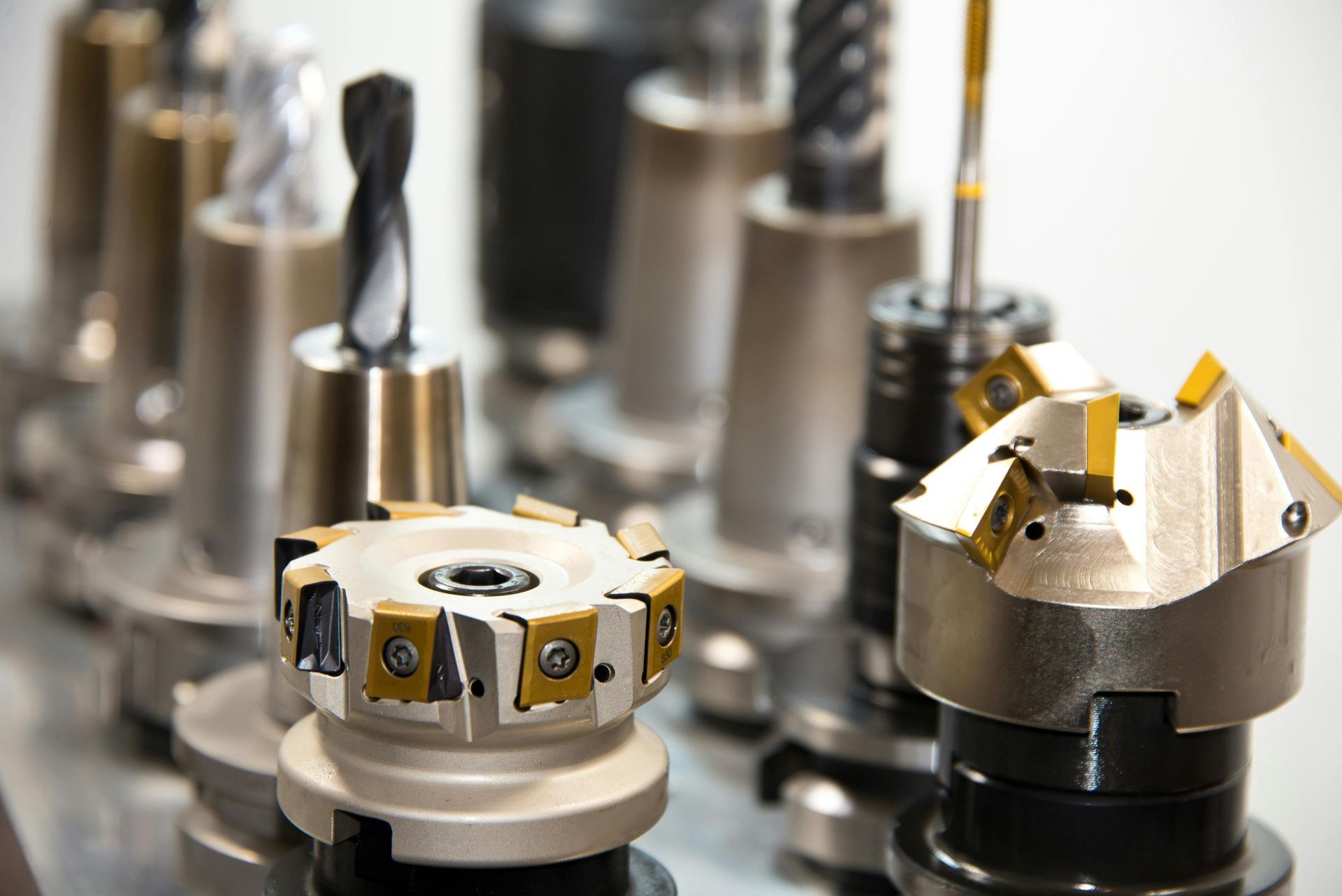

When running a metal or manufacturing shop, having the right industrial cutting tools isn’t just helpful — it’s critical for productivity, safety, and precision. Whether you're fabricating sheet metal, machining components, or assembling heavy-duty parts, your results depend on the quality and suitability of the tools you’re using.

At Williams Industrial Supply Inc., we’ve been a trusted industrial cutting tools supplier to Scranton-area businesses for nearly four decades. In this article, we break down the top 5 essential cutting tools every fabrication shop should have on hand — and how to get them fast.

Why Cutting Tools Matter in Fabrication

Industrial cutting tools allow shops to:

- Shape, size, and separate materials efficiently

- Produce consistent results on metal, plastic, and composites

- Meet tight tolerances for part production

- Minimize waste and reduce tool change downtime

- Improve operator safety and reduce fatigue

With the right tools, fabrication becomes faster, cleaner, and more profitable.

The Top 5 Cutting Tools Every Shop Needs

1. End Mills

End mills are used extensively in milling applications for contouring, slotting, and profiling.

Types Available:

- Square end

- Ball nose

- Corner radius

- Roughing end mills

Materials:

- High-Speed Steel (HSS)

- Carbide

- Cobalt

Use Cases:

Ideal for CNC machining, manual milling, and high-precision work in aluminum, steel, and stainless.

Why It’s Essential:

End mills are the workhorses of modern machining and metal shaping.

Available at Williams:

We stock and source a wide selection of standard and specialty end mills, including variable flute geometries and coatings like TiN, TiAlN, and ZrN.

2. Annular Cutters (Slugger Bits)

These hollow drill bits are perfect for boring large-diameter holes through structural steel, I-beams, and plate.

Benefits:

- Faster than twist drills

- Leaves a clean, burr-free hole

- Requires less pressure

Applications:

Structural steel fabrication, rig building, heavy equipment maintenance.

Why It’s Essential:

If you're doing heavy drilling with magnetic drills, you’ll save time and effort with annular cutters.

Brands We Carry:

Hougen, Evolution, and others.

3. Carbide Burrs and Rotary Files

Carbide burrs are essential for precision grinding, shaping, and material removal in hard-to-reach areas.

Common Uses:

- Deburring machined edges

- Cleaning up welds

- Porting cylinder heads

Shapes:

- Cylindrical

- Oval

- Flame

- Tree

- Cone

Why It’s Essential:

A must-have for maintenance teams and finishing departments where tight detail work is required.

Available Grits and Coatings:

We offer fine, medium, and coarse burrs, with and without specialized coatings.

4. Bandsaw Blades

Bandsaws are a staple in cutting structural material, bar stock, tubing, and profiles.

Blade Types:

- Bi-metal (flexible and long-lasting)

- Carbide-tipped (for hardened materials)

- Carbon steel (general use)

Why It’s Essential:

Quality bandsaw blades reduce vibration, extend tool life, and speed up cutting tasks.

We Provide:

Custom blade lengths, tooth geometries, and bulk ordering options for frequent users.

5. Cold Saw and Chop Saw Blades

For precision cuts on metal tubing, pipe, and solid bars, cold saws and abrasive chop saws are common in fabrication shops.

Blade Types:

- Abrasive blades for ferrous materials

- Carbide-tipped blades for non-ferrous

- High-speed steel for cold saws

Why It’s Essential:

These blades offer clean, square cuts and reduce the need for secondary finishing.

At Williams:

We stock standard diameters and tooth counts, and can special-order OEM blades for your equipment.

Local Availability: Why Buy Cutting Tools from a Scranton Supplier?

Immediate Pickup or Delivery

No need to wait for out-of-state shipping or backorders. We carry popular tools in stock at our Scranton warehouse.

Expert Guidance

Not sure which coating or geometry to choose? Our staff can recommend the best tool for your material, speed, and finish requirements.

Competitive Pricing

We offer bulk discounts and account terms for high-usage shops. Plus, we’ll often beat big-box pricing.

Cross-Reference Help

Have a part number from MSC, Grainger, or McMaster-Carr? We’ll find the matching or better tool from our supply network.

What Else Do We Stock?

Besides cutting tools, our Scranton location also supplies:

- Abrasives (discs, belts, wheels)

- MRO chemicals and lubricants

- Industrial adhesives and sealants

- Maintenance tools and PPE

We are a full-line industrial supply partner for shops across Northeastern Pennsylvania.

FAQs About Industrial Cutting Tools

Do you carry carbide and high-speed steel tools?

Yes. We offer HSS, cobalt, and solid carbide tools in a range of geometries and coatings for various materials.

Can I get custom or odd-sized end mills?

Absolutely. We source custom end mills and special tooling from trusted partners. Lead times vary, but we can expedite when needed.

Do you stock replacement blades for specific saw models?

We carry a wide variety of standard blades and can source or cut to length for your model. Bring your specs or old blade to match.

Do you offer delivery in Scranton?

Yes, we offer local delivery to businesses in Scranton and surrounding towns. Same-day options are available for in-stock items.

Why Fabricators Trust Williams Industrial

Since 1985, Williams Industrial Supply Inc. has supplied cutting tools to:

- Machine shops

- Metal fabricators

- HVAC contractors

- Maintenance teams

- Welding and repair shops

We don’t just sell tools — we help shops work smarter and more efficiently with quality products, expert service, and fast turnaround.

Visit or Call to Order

Williams Industrial Supply Inc.

916 N Washington Ave

Scranton, PA 18509

Phone: (570) 347-2015

Email: tonyatwilliams@epix.net

Hours: Mon–Fri 8:30am–5:30pm

Need industrial cutting tools you can rely on? Call Williams Industrial Supply for expert help, fast local pickup, or same-day delivery. Get the tools your shop needs — without the wait.